Modules

Maintenance

Equipment upkeep is part of the daily routine for many businesses—and it’s more critical than it seems. Without proper maintenance, vehicle and machinery issues can lead to unplanned downtime, expensive repairs, and even stopped worksites. Kiho’s Maintenance module makes servicing structured, proactive, and easy to manage.

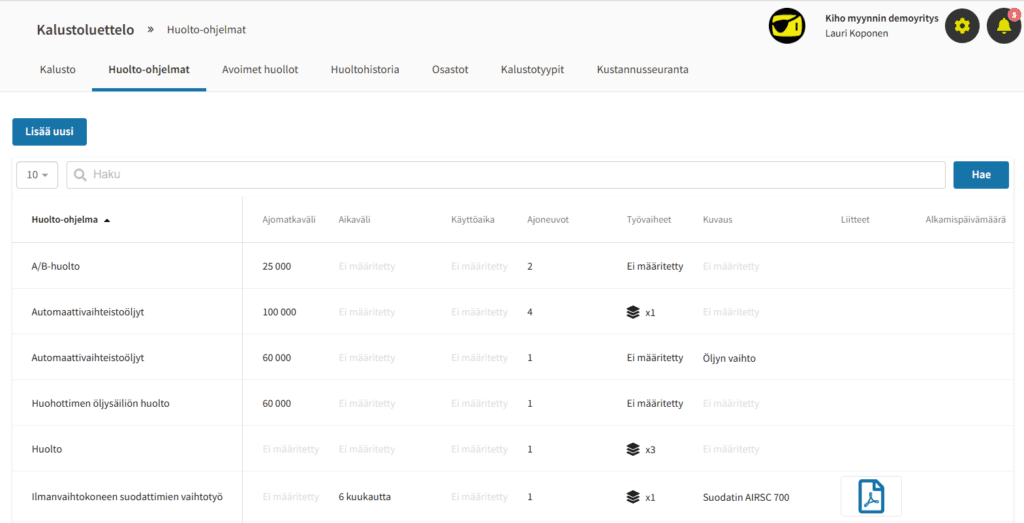

All service records, fault reports, and maintenance schedules are stored in one place, making it simple to plan, monitor, and track work. Automated reminders and predictive maintenance features help your business stay one step ahead—keeping equipment ready and operations running smoothly.

Keep your company’s equipment in working order, and anticipate maintenance with plenty of time to spare

Without proper maintenance management, a company’s fleet operates in a state of guesswork and hope. Machinery might be sent out at the wrong time or, in the worst case, break down mid-job. Kiho’s maintenance module keeps vehicle and machine data up to date and easy to access. No more hauling an excavator 200 kilometres to a site only to discover it needs an oil change.

When maintenance history, fault reports, and predictive servicing plans are all in one system, companies can avoid unnecessary repairs and keep equipment available when it’s needed most. Maintenance can be scheduled based on hours of use, kilometres driven, or set calendar intervals, so servicing happens at the right time—not too early and not too late.

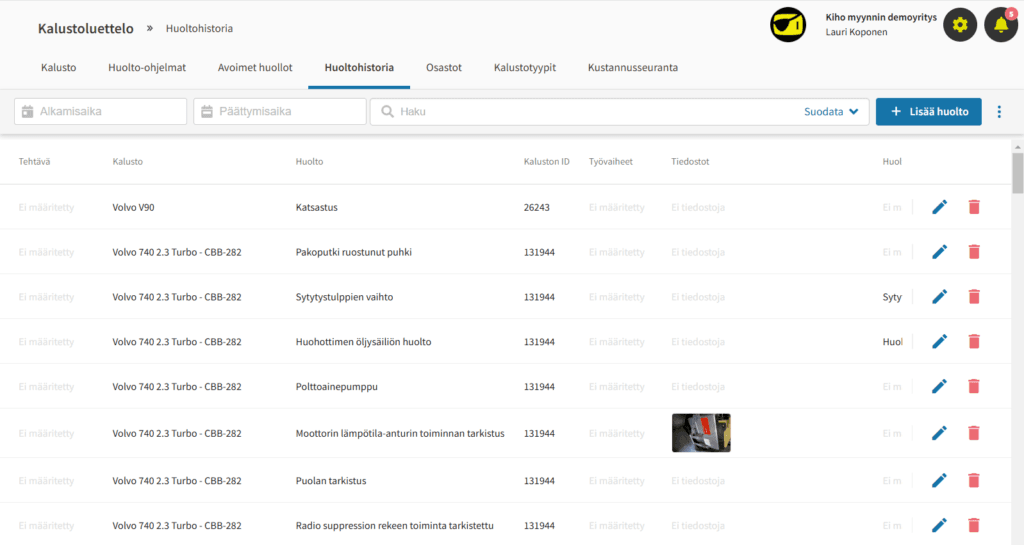

Workers and drivers can report faults directly from the field and attach photos when needed, speeding up the repair process and cutting downtime. With data flowing automatically into the system, it’s easy to respond to issues quickly and plan repairs without delay.

How Kiho’s Maintenance Module Works in Practice

1.

Log and Manage All Maintenance from One Place

All service records are stored in the system, so every vehicle’s and piece of equipment’s maintenance history is clearly documented.

Example: An oil change is performed on an excavator; the service date and performed tasks are entered into Kiho. That information is immediately visible to other users, letting the machine get back into operation quickly and helping you plan the next service efficiently.

2.

Proactive Maintenance Scheduling

Set up maintenance programs based on usage. Services can be scheduled by miles driven, operating hours, or preset calendar dates.

Example: A crane is assigned a maintenance schedule that alerts the fleet manager when it reaches 500 operating hours. This means your service cycle is always under control.

3.

Fast Fault Reporting from the Field

Employees can report faults directly through the mobile app. Reports can include photos and notes so the maintenance team has all the necessary information right away.

Example: A driver notices a leaking hydraulic hose. They submit a fault report via the app and attach a photo of the leak. The maintenance team sees it immediately and can plan the repair and order parts in advance.

4.

Link Maintenance to Task Management

When maintenance jobs are tied into Kiho’s Tasks module, work orders can be assigned and tracked efficiently. You’ll know exactly how many resources were used and whether the job was cost-effective.

Example: The maintenance manager configures all oil changes and brake inspections as tasks for the service team. Each job is clearly scheduled, and operations supervisors can monitor which services have been completed.

Combine with other Kiho modules and maximise power

The Kiho Maintenance module works smoothly alongside all other Kiho modules. Customers using Maintenance have seen the biggest benefits when combining it with Fleet Management, Telematics and Tasks. When everything is connected, the system functions as a complete solution, not almost, but fully.

With maintenance history stored in the same system as fleet data, it becomes easier to make informed decisions about servicing schedules and equipment lifecycle management.

Kiho also makes it possible to link maintenance data directly to your financial management systems. Maintenance-related costs can be recorded and analysed within your accounting software, while cost items tagged to the fleet can be imported back into Kiho to generate entries and support fleet cost tracking.

Why is maintenance management an important part of business?

Maintenance management is much more than just fixing faults. By systematically planning and monitoring maintenance, a company can reduce downtime, extend the life of its equipment and avoid unnecessary repair costs.

With maintenance history and predictive maintenance programmes always available, decisions on fleet maintenance are made easier. Failure notifications by employees speed up maintenance actions and reduce the risk of a small failure developing into a larger problem.

Systematic maintenance management reduces costs and optimises the use of resources.

One Kiho, total control, better reliability

Kiho’s Maintenance module ensures that your company’s equipment stays in good condition and in use without any unnecessary surprises. With all maintenance information, fault notifications and maintenance schedules in one place, your business will run more smoothly and efficiently.

Kiho makes fleet maintenance controlled, proactive and easy.